- Summary

- What Is 3D Product Configuration and Why Does It Matter in Web-to-Print

- Real Industry Use Cases of 3D Configurators

- Key Features to Look for in a 3D Product Configuration Tool

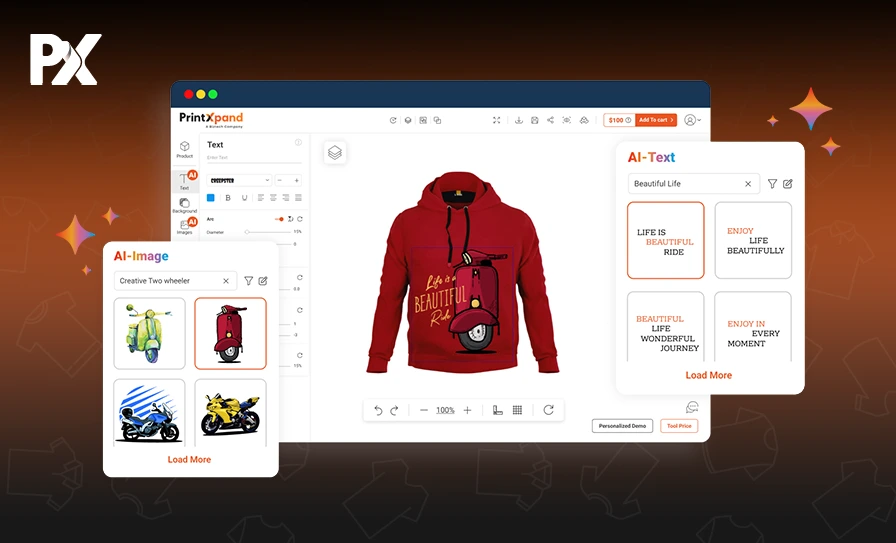

- How PrintXpand’s 3D Designer Stands Apart

- The Measurable Business Impact of 3D Product Configuration

- Expert Tips for Getting Started with 3D Configuration

Summary

A buyer wants customized T-shirts. They select the material, sleeve length, neckline, upload the artwork, and then pause, thinking, “What will this actually look like?” The preview doesn’t show the texture, design placement, and the product just feels… unfinished.

They hesitate. They abandon the quote. And in 2025, this uncertainty kills conversions!

Let’s be clear that this isn’t a small UX issue. It’s a scalable revenue leak for web-to-print businesses like yours.

Your clients expect complex product configuration, including materials, finishes, folds, and textures. Yet most platforms still show only flat 2D previews or static PDF proofs, which fail to build confidence.

Reports show that adding 3D product content can reduce return rates by up to 40%. In fact, 89% of retailers agree that 3D content significantly helps prevent returns.

Even US-based Rowe Furniture recently reported that their B2B online sales doubled since launching 3D product visualization. This is the kind of immersive 3D product configuration that solves the ‘guesswork’ issue by offering real-time, 360° visualization and part-by-part customization. And, today, that’s exactly what buyers expect to see before they click “Buy.”

Let’s further discuss how web-to-print leaders use interactive product configurators and real-time 3D configurator tools to double their conversions, reduce returns, and streamline every custom order.

What Is 3D Product Configuration and Why Does It Matter in Web-to-Print

Generally speaking, 3D product configuration allows buyers to interact with a virtual version of a product in real time. They can change its structure, style, and design, and instantly see every update from all angles.

In the web-to-print world, this means your customers can build their own version of a product. It can be any product, be it a T-shirt, hoodie, or packaging box, by selecting materials, sleeve or collar types, adjusting dimensions, uploading their artwork, and more. They can zoom, rotate, and explore the product in full detail before placing an order.

Now, here’s where it gets important: product configuration and customization aren’t the same thing, even though they’re often used interchangeably.

- Product Configuration is about structure. It covers choices like fabric type, component style, finishes, cuts, folds, etc. In short, things that define the product’s physical form.

- Product Customization, on the other hand, is about design. It’s where your customers add personal elements such as logos, text, images, colors, or patterns to make the product their own.

However, the pressing challenge in this scenario is that most traditional businesses still rely on 2D previews or static PDF proofs. Let’s be real, these flat visuals don’t capture the real product experience anymore. As a result, customers are left guessing what the product will look like, leading to more mismatched expectations, longer approval cycles, refunds, or costly reprints.

But with a real-time 3D configurator, they get a true-to-life view of what they’re buying. This level of interactivity leads to:

- More confident purchase decisions

- Fewer design-related support queries

- Significantly lower return rates

- Longer engagement and higher conversion rates

Real Industry Use Cases of 3D Configurators

In 2025, modern B2B buyers, especially those ordering apparel, uniforms, promotional items, or product packaging, expect an immersive, self-service experience. And a 3D product configuration delivers just that.

The true strength of 3D configurators lies in how flexibly they adapt across industries with different needs, products, and buying behaviors.

The challenges may vary from personalized apparel to modular furniture, but the solution stays consistent—giving users full control, real-time visibility, and fewer reasons to second-guess the order.

Here’s how different web-to-print businesses are applying real-time 3D product configuration to reduce friction, improve workflows, and deliver a better buying experience.

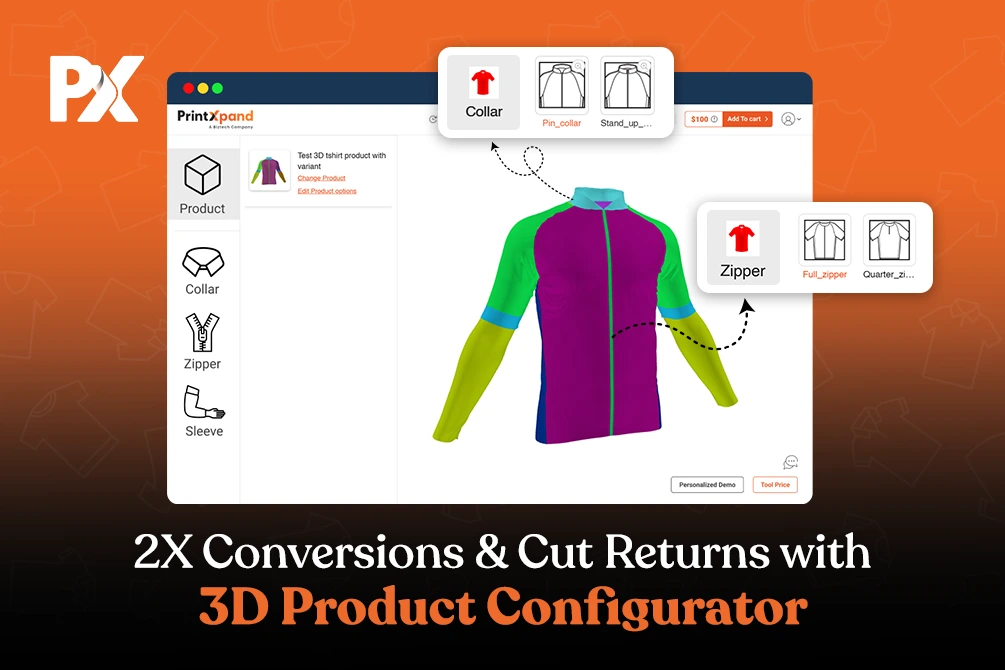

#1. Apparel: T-Shirts, Jerseys, Uniforms, Shirts, Hoodies

Challenges:

Bulk apparel orders often involve multiple SKUs, variable branding zones, and fabric-dependent color outcomes. Most teams still rely on flat 2D previews, email chains for revisions, and static PDF proofs, all of which make it difficult for customers to accurately visualize the end product. This slows approval cycles, increases production errors, and leaves room for interpretation, especially when different departments are involved.

The solution:

A 3D product customizer solves this by letting users configure every aspect of the garment—necklines, sleeve lengths, fits, and fabric types while uploading artwork and seeing exactly how it wraps around the product in 360°.

Impact:

- Accelerates design approvals and reduces turnaround time

- Minimizes reprints caused by misaligned visuals

- Streamlines personalization at scale with less manual effort

Use cases in action:

- Sports teams ordering personalized jerseys

- Schools/universities ordering event or team uniforms

- Fashion retailers offering custom fits/styles online

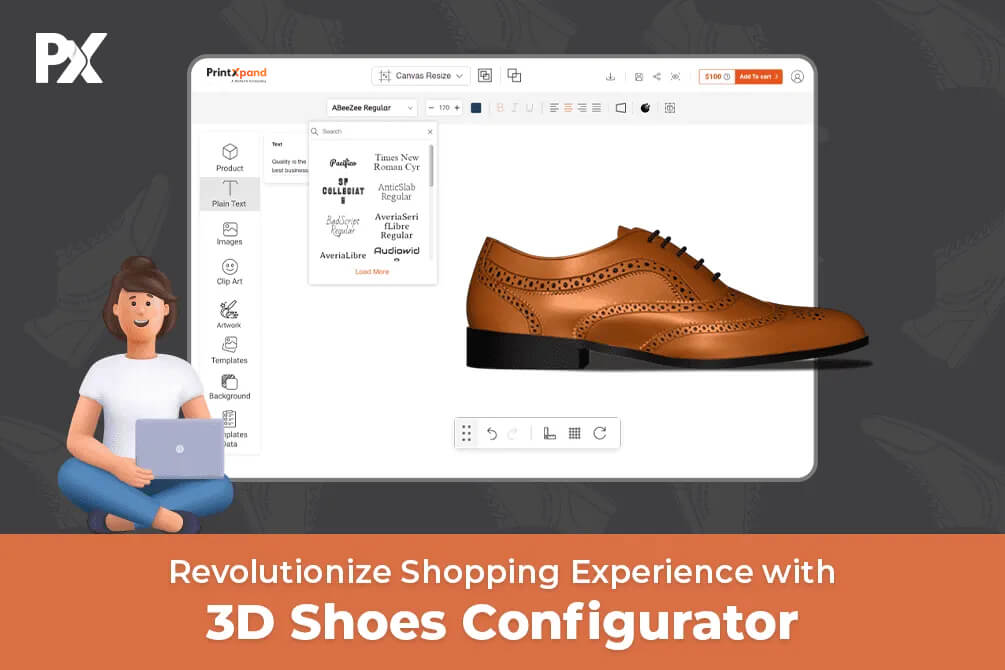

#2. Footwear: Sneakers, Sports Shoes, Formal Shoes, Safety Shoes

Challenges:

Custom shoes require a high level of detail—laces, soles, toe shapes, panel colors. Without a visual preview, people hold back. And for bulk B2B orders, that uncertainty means fewer orders or repeated revisions.

The solution:

A real time 3D configurator lets customers adjust every part of the shoe and see it come to life instantly. Paired with dynamic pricing for configurable products, they also understand exactly how each choice affects cost.

Impact:

- Boosts buyer confidence and increases order value

- Minimizes back-and-forth on design details

- Reduces returns, even for highly personalized items

Use cases in action:

- Safety shoe brands offering company co-branded gear

- Sneaker startups letting users design custom kicks

- Businesses ordering footwear in bulk with individual personalization

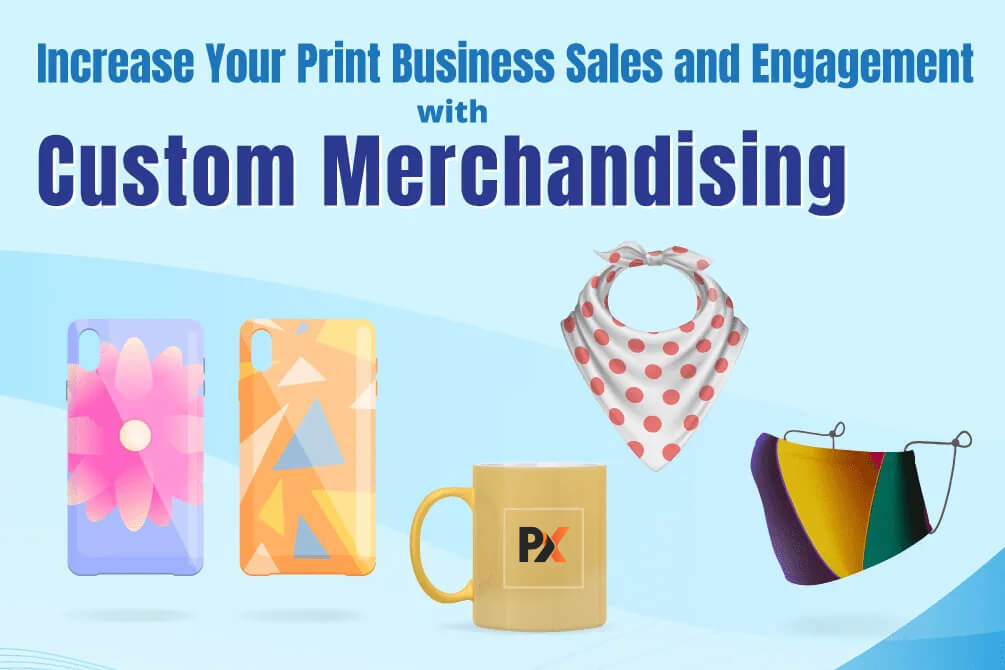

#3. Promotional Products: Caps, Bags, Bottles, Jackets

Challenges:

Promotional product buyers often work on tight deadlines with strict brand guidelines and varying print methods such as screen printing, embroidery, sublimation, etc. Traditional mockups can’t show how logos will appear across fabric types, embroidery zones, or curved surfaces like bottles. Without live previews, teams request multiple revisions or samples, dragging out the sales cycle.

The solution:

With an interactive product configurator, customers can upload their artwork, apply it to multiple products like caps, bags, bottles, or jackets, and preview how it will look. They can also test color variations, change the fabrics, and even visualize logo placement based on decoration zones. When bundled with dynamic pricing and quantity selectors, B2B customers can get instant clarity on cost.

Impact:

- Speeds up client approvals and shortens sales cycles

- Prevents costly production errors and miscommunication

- Increases AOV through real-time bundling and upselling

- Event organizers customizing giveaways (bags, bottles)

- Corporates customizing employee kits

- Merch sellers designing promotional apparel plus accessories

#4. Furniture and Large Items: Chairs, Sofas, Cycles, Office Desks

Challenges:

Configurable furniture or equipment orders come with multi-part complexity in terms of materials, sizes, attachments, upholstery, and finish combinations. In the B2B space, especially, orders often pass through multiple approvers (procurement, design, operations). That makes it even more important to align everyone with a clear, shared visual. Unfortunately, traditional product sheets and static images rarely provide the context needed to show how modular components come together, leading to longer cycles and costly revisions.

The solution:

A 360-degree product viewer gives buyers full control over every customizable component—whether it’s swapping upholstery, adding/removing armrests, or configuring dimensions. One can see visual consistency across units, validate decisions together, and place accurate bulk orders. With features like CSV import, mobile access, and product design automation, large-scale configurations become seamless.

Impact:

- Shortens decision timelines for complex, high-ticket orders

- Eliminates errors through clear, visual configuration

- Enhances the buying experience for both B2B and B2C buyers

Use cases in action:

- Interior brands offering sofa or chair customization

- Corporate procurement customizing office furniture

- Specialty stores offering niche items like ergonomic cycles or foldable desks

Key Features to Look for in a 3D Product Configuration Tool

Not all 3D configurators are built equally, and when you’re handling B2B workflows, custom orders, or high-SKU catalogs, the difference between a flashy demo and a scalable solution becomes very real, very fast.

Although we’ve touched on many of these features throughout the blog, let’s just lay them all out clearly and ‘understand’ them in depth! These are the must-haves that turn a good configurator into a scalable solution for your web-to-print business.

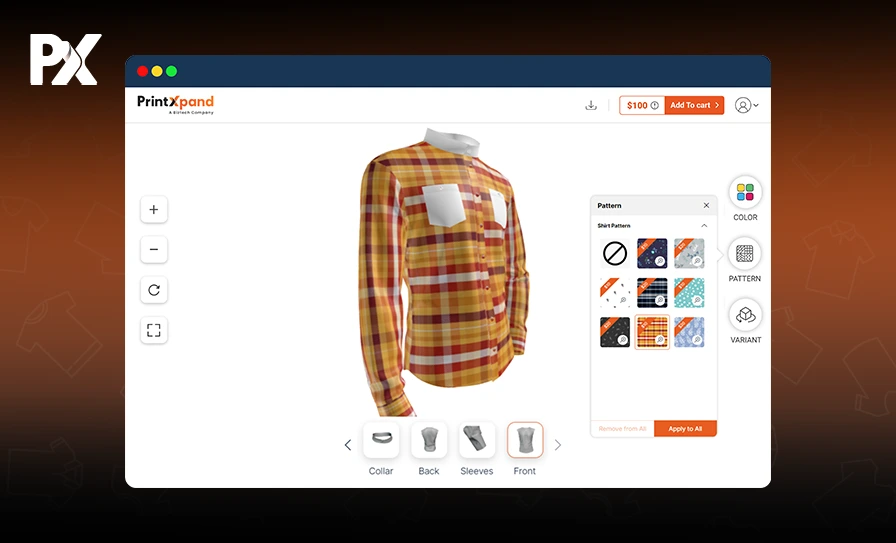

360° Visualization

Buyers want to see what they’re getting from every angle, especially when ordering in bulk. A configurator, thus, should offer smooth, full-angle previews with the ability to rotate, zoom, and inspect texture details. Whether it’s a stitched logo on a sleeve or the material finish on a desk leg, visual context is what builds buying confidence!

Use Case: A school ordering custom uniforms for multiple campuses can approve branding placement instantly, without needing multiple samples.

Part-by-Part Configuration

The configurator should allow users to modify specific components like sleeves, collars, soles, handles, or panels depending on the product. More than just ensuring the aesthetics are in place, it also supports SKU-level logic for B2B workflows. Further, it also makes sure that each configurable part maps accurately to production.

Use Case: A sneaker brand lets users choose lace style, tongue material, and sole color, each change updating live in the preview.

Dynamic or Live Pricing

As customers configure their product, pricing should update in real time based on materials, quantities, print methods, or design complexity. This helps buyers stay within budget and reduces friction near checkout, especially for large or bundled orders.

Use Case: A corporate merch buyer selects embroidered branding instead of screen print and instantly sees the updated unit price.

Image Upload with Auto-Color Detection

Uploading logos or artwork should be seamless and smart. Tools with auto-color detection can extract the color palette from uploaded files, helping with color matching and ensuring brand consistency across multiple products or variants.

Use Case: A marketing agency uploads a logo once and automaps its color palette across bottles, bags, and jackets in order.

In-Built Designer Studio

A configurator should come with an embedded design studio where users can add text, clipart, images, and AI-generated prompts. This reduces dependency on external tools and makes the platform feel more intuitive, plus 360-degree, specifically for non-design-savvy buyers.

Use Case: A merch seller personalizes a jacket with team names, brand slogans, and clipart directly within the same interface.

Mobile-First Interface

Many B2B buyers work across devices, not just from behind a desk. They’re reviewing, approving, and editing orders on the move. That’s why a truly effective 3D product customizer needs to be fully mobile-friendly, alongside having a smooth performance across devices, intuitive drag-and-drop controls, pinch-to-zoom capability, and fast load times.

Use Case: An event organizer finalizes a bulk cap order from their mobile during a site visit, without needing desktop access.

CSV Import for Bulk Orders

When dealing with bulk orders, the buyers need to configure multiple units with individual details such as names, sizes, and colors. Therefore, it is important that the 3D product customizer supports CSV uploads, enabling fast, accurate ordering at scale without manual intervention.

Use Case: A uniform supplier imports 500 employee shirt orders with unique names and sizes using a simple CSV template to get print-ready files of each shirt.

Lightweight, High-Performance Build

All the features in the world won’t matter if the tool slows down when it counts. Your 3D configurator needs to be fast, reliable, cloud-based, and built to perform even in low-bandwidth environments. Especially for teams spread across geographies or working with varied tech setups, consistent performance is just the baseline for usability.

Use Case: A furniture distributor in a low-connectivity region completes a full product configuration workflow without delays or load failures.

When you’re choosing a 3D configurator, don’t think that these are some bonus features because they’re fundamentals. The right tool should enable your customers to configure, customize, preview, and order with confidence while your team handles less back-and-forth and more fulfillment.

See how PrintXpand’s interactive 3D configurator does it all!

How PrintXpand’s 3D Designer Stands Apart

While many 3D product configuration tools are built for high-end fashion or enterprise-level retail, PrintXpand has designed it specifically for web-to-print businesses offering custom apparel, packaging, promotional products, or bulk personalized items.

It’s not a complex enterprise system or a one-off custom build. Instead, we offer a plug-and-play 3D product customizer that works seamlessly with:

- Magento

- Shopify

- WooCommerce

- Odoo

The interactive product configurator focuses on what matters the most:

- It’s lightweight and cost-effective, meaning you don’t need to invest $50,000–$100,000 in custom development just to get started.

- It’s built for performance, offering fast, responsive experiences, even when handling complex product structures or large-volume configurations.

- With built-in SKU-level logic and CSV import support, it’s ready for real-world B2B workflows where orders often include multiple variants and personalized fields.

- It’s fully mobile-friendly and cloud-based, so there’s no need for local installs or downloads, and it performs smoothly even on moderate connections.

And because our team handles the technical heavy lifting like ongoing support, updates, and platform compatibility, you stay focused on selling, not maintaining infrastructure.

So, if you’re looking for a 3D configurator that’s built for web-to-print, adapts to complex B2B workflows, and scales as your product catalog grows, we’ve designed it to meet that need.

The Measurable Business Impact of 3D Product Configuration

Adopting a 3D product configurator goes beyond visual appeal. For web-to-print businesses, it directly improves how orders are placed, approved, and fulfilled, while contributing to measurable gains across key metrics.

Here’s what businesses typically achieve with a real-time 3D configurator:

- 30–60% lower bounce rates on product pages that offer live, interactive previews

- 15–25% reduction in returns, due to better clarity around customization and final product expectations

- 2x faster order processing, supported by visual confirmations and bulk CSV imports

- Higher conversions and average order value (AOV) as users explore upgraded materials and add-ons during configuration

- $50K–$100K in cost savings, compared to developing a custom 3D engine from scratch

- Improved scalability, without adding technical complexity or ongoing development overhead

Each of these gains contributes to more efficient workflows, better customer experiences, and a stronger bottom line.

Expert Tips for Getting Started with 3D Configuration

If you have made up your mind and wish to implement a 3D product configurator in your web-to-print business, then these practical steps will help you prepare for it.

Step 1: Audit Your Current Workflow

Start by mapping out how your current order process works, right from how assets are managed to how approvals are handled, and how pricing is calculated. Once that’s clear, identify the manual steps that could be automated through a web-to-print solution. This will help you spot the biggest opportunities for efficiency.

Step 2. Check Product Compatibility

Not every product in your catalog needs 3D visualization. Focus on SKUs where visual representation truly impacts customer decision-making, like apparel, packaging, or trophies. For simpler items such as business cards or flyers, 2D previews may be sufficient.

Step 3. Prepare Product Assets

To ensure a smooth experience, use optimized 3D or 2D files that include proper lighting, UV mapping, and annotations. Also, make sure your fonts, color palettes, and clipart libraries are organized and aligned with your brand or client requirements.

Step 4. Test All Use Cases

Before going live, test your configurator across a wide range of scenarios, such as different screen sizes, file upload types, low internet speeds, and checkout flows. Simulate real customer behaviors, including edge cases like bulk orders, unusual fonts, or large uploads, to ensure everything works as expected.

Curious what kind of results you could see with 3D configuration?

See how PrintXpan’s configurator fits into your existing workflow—without the overhead or complexity.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.