Summary

Print manufacturing is all about coordination. And when that coordination runs on spreadsheets, delays and errors become part of the routine. Your production floor may be cutting-edge, but if your BOM management software is a patchwork of Excel files and your print job scheduling software is just sticky notes, you’re fighting a losing battle every day.

The stress of juggling disconnected tools while managing print production causes chaos that spreads across your entire operation! Teams waste hours reconciling information, customers wait longer for deliveries, and growth feels impossible when you’re constantly putting out fires instead of focusing on what matters most.

This is the transformation story of how one print manufacturer transitioned from manual chaos to automated efficiency using PrintXpand ERP. It’s a workflow-aware automation system specifically designed for both manufacturing and trade operations in the printing industry. Here’s how they streamlined their entire BOM and production process without disrupting their team or business.

Key Takeaways

- Managing print production and inventory manually can result in errors, delays, and team coordination breakdowns.

- Print manufacturing workflow automation can solve these problems by automating job order management and combining BOM management software with real-time inventory updates.

- PrintXpand ERP, for example, is a print production management system that automates work orders and schedules jobs.

- Reducing print production errors with ERP software may boost accuracy, efficiency, and consistency while saving time and money.

- Automated print inventory management provides firms with real-time visibility into material levels, eliminating stockouts and waste.

- Automated job order management enables print producers to increase operations while reducing manual complexity.

The Challenge

Suppose that your production team starts each morning not knowing exactly what materials they need, which jobs are priority, or whether inventory levels can support the day’s scheduled work. This was reality for a growing print manufacturer whose manual processes had become its biggest bottleneck.

Managing print production and inventory manually challenges even the most experienced teams. That, in turn, leads to constant coordination breakdowns, missed deadlines, and material mismatches.

Their daily struggles included:

- Disconnected BOM management

BOMs lived in spreadsheets with no connection to live inventory or SKU variations. When orders came in, someone had to manually cross-reference materials, hope the quantities were accurate, and pray nothing had changed since the last update.

- Outdated work orders

Work orders were either handwritten or created using static templates that were often incomplete or outdated by the time they reached the production floor.

- Communication chaos

Job status updates happened through a chaotic mix of emails, chat messages, and verbal communication. Production managers spent more time hunting down information than actually managing production.

- No standardization

Each job felt like starting from scratch, even for repeat orders, because there was no consistent process or template to follow.

- Reactive inventory tracking

Print inventory management was purely reactive. Inventory levels were updated after production was complete, leading to frequent stockouts that stopped jobs mid-process or overstocking that tied up working capital.

- Split system management

When orders included both in-house printed SKUs and traded products, they had to be split and managed in completely different systems, creating even more coordination overhead.

The result was constant miscommunication, wasted materials, and delayed deliveries. Instead of focusing on quality manufacturing workflow automation, the team felt like they were drowning in administrative tasks.

The Solution?

PrintXpand ERP transformed this chaos by digitizing and automating every stage of the manufacturing workflow, creating a seamless print production management system that actually understood how print businesses operate.

Key automation improvements that were made:

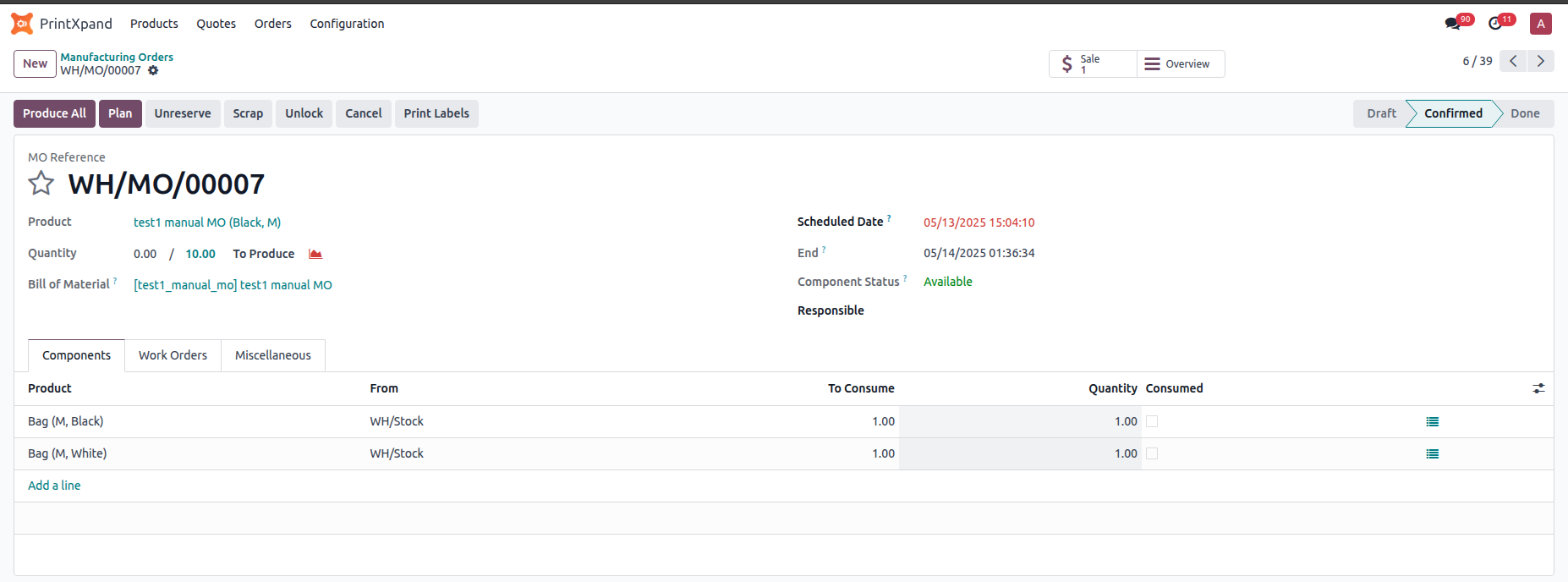

- Automated BOM setup

Each SKU now had its own dynamic BOM preconfigured in the system. The moment an order was confirmed, the system automatically attached the correct BOM to the manufacturing order. In short, no more manual lookups, no more guessing, and no more errors from using outdated spreadsheets!

- Pre-built work order templates

Every day tasks were templatized to eliminate repetitive manual entry that consumed hours each week. This ensured consistency in execution while allowing for flexibility in meeting unique requirements.

- Auto-generated job cards

Work orders were created instantly upon order confirmation, eliminating the delays in production initiation that previously plagued the start of every job.

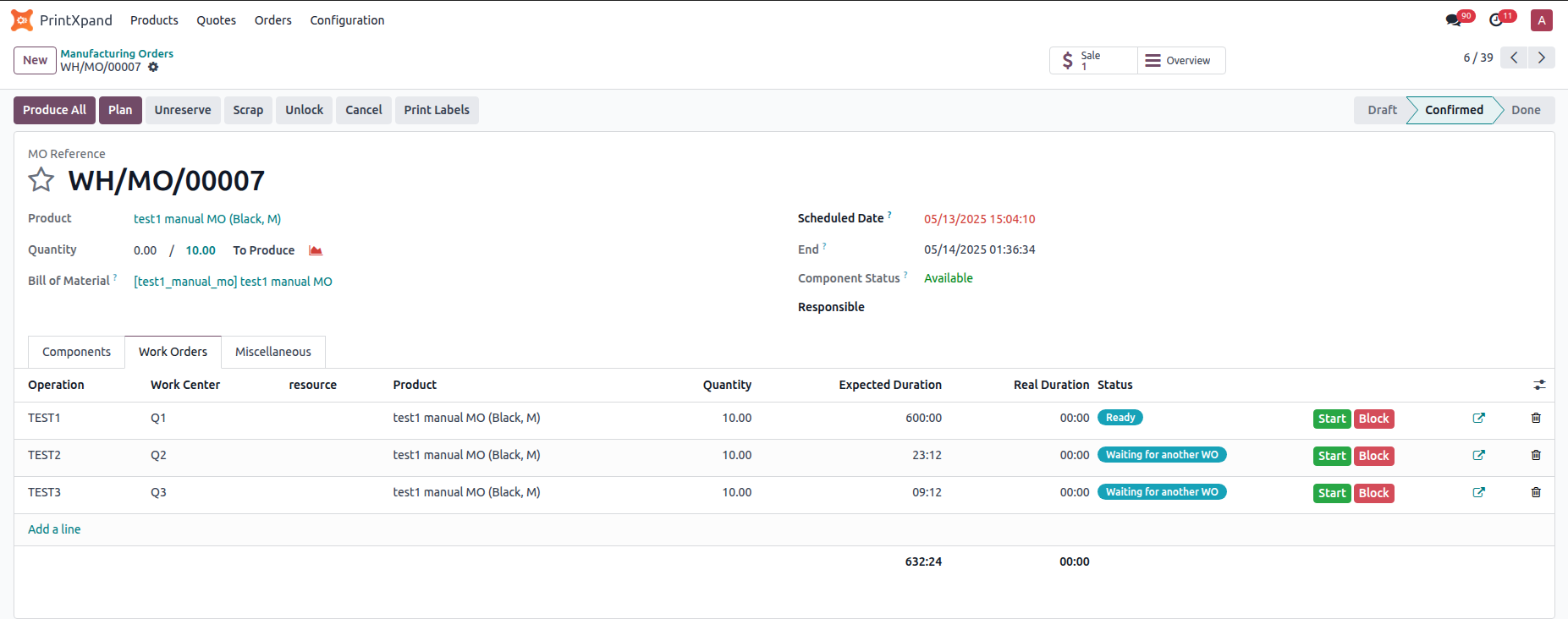

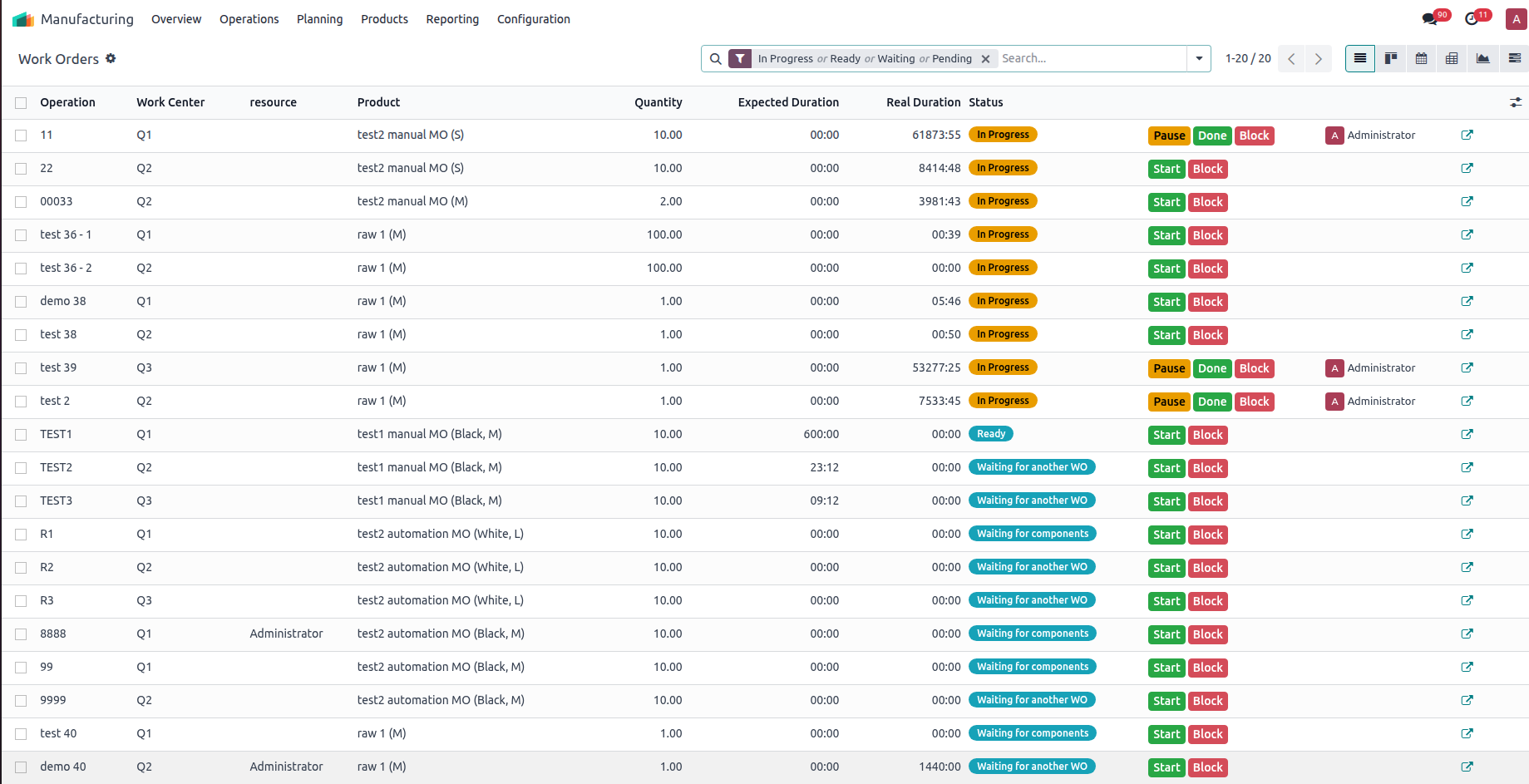

- Intelligent scheduling

The system’s work center and employee scheduling automatically assigned jobs to specific machines or staff based on availability and priority. No more morning huddles trying to figure out who should work on what. The print job scheduling software handled it intelligently.

- Live production tracking

Managers gained real visibility into shop floor progress. Staff could update job status in real-time, immediately flagging delays or bottlenecks before they became major problems. This wasn’t just about data collection; it was about creating accountability and transparency throughout the entire manufacturing workflow automation process.

- Real-time inventory sync

Inventory was updated automatically as production consumed materials. Real-time updates prevented manual reconciliation errors and gave accurate visibility into what was available for upcoming jobs. No more production stops due to surprise stockouts.

The hybrid order breakthrough:

Perhaps most importantly, the system handled hybrid orders intelligently. Orders containing both manufactured and traded SKUs were automatically routed through the appropriate workflows. Manufactured items triggered production flows, while traded items triggered purchasing flows with automatically generated supplier POs. To put it precisely, one order, multiple fulfillment paths, and zero manual intervention.

The ERP system was truly workflow-aware, recognizing that print manufacturing is more than just production. It’s about coordinating complex processes that span from initial order to final delivery.

The Results

The transformation was operational as well as measurable. Here’s what the numbers revealed:

Error reduction and efficiency gains:

- 70% reduction in manual errors, particularly in BOM selection and work order documentation. What used to be a source of constant stress and rework became reliable and consistent. Reducing print production errors with ERP software not only improved consistency but also allowed the team to trust the system for every stage of the job lifecycle.

- 2-3 hours were saved daily in coordination time between production, inventory, and procurement teams. Instead of chasing information and reconciling discrepancies, they could focus on optimizing processes and improving quality.

- There was an 80% faster BOM creation since components were pre-attached and reusable across similar jobs.

Delivery and cost improvements:

- 40% improvement in on-time job deliveries because of the standardized processes and real-time job tracking. Customers noticed the difference, and the sales team could confidently promise delivery dates knowing the system would support them.

- Significant decrease in material wastage due to accurate real-time inventory tracking and proper BOM management.

- Better cost control as managers had visibility into exactly what materials were being consumed for each job.

Scalability breakthrough:

The business became more scalable, and the system handled increasingly complex workflows without adding manual workload or requiring additional coordination staff.

Most importantly, the team’s stress levels dropped dramatically. Instead of fighting their tools and processes, they could focus on what they did best: producing high-quality print products efficiently.

Why PrintXpand ERP Was the Right Fit

Generic ERPs and traditional MIS tools often fail in print manufacturing because they don’t understand the unique complexities of the industry. PrintXpand ERP succeeded because it was built specifically for printing businesses, understanding SKU variants, job card formats, and the hybrid nature of modern print operations.

What made PrintXpand different:

- Industry-specific design

Unlike other systems that force you to choose between trading and manufacturing workflows, PrintXpand seamlessly blends both. This is ideal for printers who both outsource certain jobs and produce others in-house.

- Easy implementation

The system’s modular, web-based design reduced the learning curve significantly. Teams didn’t need extensive retraining, and implementation didn’t disrupt day-to-day operations.

- Flexible integration

The system integrated easily with existing processes rather than forcing a complete overhaul of established vendor relationships or business logic.

- Practical automation

PrintXpand ERP automates only what matters, making it practical for real businesses. There is no overengineering or excessive complexity; instead, intelligent automation solves the day-to-day difficulties that print manufacturers encounter.

Expert Tips for Successful Implementation

- Prioritize High-Impact Modules First: Don’t try to implement everything at once. In Phase 1, focus on job order automation, live production tracking, and BOM sync. These aspects usually deliver the fastest operational wins. In Phase 2, tackle advanced areas like dynamic pricing, supplier integration, or customer self-service portals. Quick wins build team confidence and generate early ROI, which helps justify

- Prepare Your Data Before Migration: Clean up your product SKUs, BOM details, customer records, and supplier lists. Don’t underestimate this step! Poor data slows down setup, causes import errors, and frustrates teams. Clean, structured data accelerates go-live and prevents early-stage trust issues in the system.

- Build Templates for Repeat Jobs: Invest time upfront in work order templates, BOM templates, and common hybrid order setups. This saves dozens of manual touches per job later and reduces errors. Pre-built templates reduce manual handling and help less experienced staff operate confidently.

- Roll Out With Pilot Teams: Don’t launch across the entire business at once. Pick a pilot team or product line to test and refine the system. Gather lessons, fix gaps, and gradually expand. Controlled pilots reduce risk, uncover blind spots, and make full rollout smoother.

- Train for Workflow, Not Just Software: Teach staff why things are changing, not just which buttons to click. What manual tasks are disappearing? What new alerts or dashboards should they watch? How does this help the business and reduce their stress? Change management is often the biggest barrier. Clear communication eases fear and accelerates buy-in.

- Keep a Feedback Loop Open: Schedule regular check-ins post-launch. What’s working? Where are the friction points? What features should be activated or customized next? ERP success is an ongoing optimization journey, not a one-time switch.

As a result, the system enables print manufacturers to reduce operational turmoil, accelerate delivery, and scale without increasing complexity. In doing so, it elevates manufacturing process automation from a source of stress to a meaningful competitive advantage.

So, if your print business is still coordinating production using spreadsheets and manual processes, it’s time to see how automated job order management might improve your operations. To get started, schedule a personalized demo to learn how PrintXpand ERP can optimize your specific workflows and reduce the everyday coordination chaos that is holding your business back.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.