Every minute lost in procurement costs you momentum—and maybe the client!

You’re juggling your third RFQ of the day, two urgent POs sit half-complete in your inbox, and the customer’s asking for artwork approvals. Meanwhile, the corporate client who placed a rush order yesterday is already asking about delivery status.

If you’ve faced this or something similar, then this blog is just for you.

Wholesale trade printers, like you, have one of the toughest coordination jobs in the print industry. You’re the air traffic controller between customers who need custom solutions and the manufacturers and print houses that make stuff happen. Even today, most wholesale trade printing operations are still managing this circus with simple spreadsheets, email chains, and phone calls that create bottlenecks right when everything needs to move fast. But what if we tell you that there’s actually a way to automate that crazy purchase order workflow that runs your life?

Key Takeaways

- Quote Time Revolution: Drop from 2-3 hours per quote to under 5 minutes with automated pricing and product validation

- Error Elimination: Manual calculation mistakes that kill 20% of quotes get eliminated through automated print order management software

- Multi-PO Automation: Generate all three coordinated purchase orders (customer, manufacturer, print house) simultaneously after order approval

- Scalability Breakthrough: Handle 3-5x more orders with the same team size through purchase order workflow automation

- Competitive Advantage: Same-day RFQ responses while competitors take days, leading to higher win rates and better margins

The Challenge: When Your Day Becomes a Game of Whack-A-Mole

Have you ever noticed how RFQs always hit your desk at the worst possible moment? Like when you’re already juggling three urgent orders and trying to track down a supplier who’s gone radio silent?

Here’s what’s driving everyone crazy: each complex quote eats up 2-3 hours of your day. You’re digging through manufacturer catalogs that seem to update every time you blink, cross-referencing print house capabilities that vary by location, and trying to factor in delivery logistics that change based on order size and timeline.

Meanwhile, your competition, using print order management software, is firing back professional quotes in 20 minutes. And all of this is happening while you’re still hunting for the right product spec sheet.

Wondering how much time you’re losing to this manual madness? Our printing estimation tool might surprise you!

The error rate is what really gets you. Manual pricing calculations go sideways about 20% of the time. Sometimes you price yourself out of deals you should’ve won. Other times, you win jobs that barely break even after factoring in real costs.

But here’s the kicker. Every time you try to scale up, the chaos multiplies. More orders? More spreadsheets. More phone calls. More chances for things to slip through the cracks. And because of all of this, you end up hiring people just to manage the administrative nightmare instead of actually growing the business.

The Use Case: When One Order Becomes a Three-Ring Circus

Last month, we talked to a wholesale trade printer who landed what seemed like a straightforward corporate order for custom T-shirts and hoodies with full-color artwork. Nice order, decent margins, happy client.

Then reality hit!

Purchase Order #1 from the corporate client appeared straightforward—quantity, design specifications, delivery location, and timeline. Standard stuff that fits on one page.

But here’s where it gets fun (and by fun, we mean incredibly frustrating):

Purchase Order #2 had to be sent to the T-shirt and hoodie suppliers first, since they couldn’t be shipped to the client. Why? Because they have to go directly to the print house for customization. So now the printer was coordinating delivery timing between two different vendors, making sure the T-shirts and hoodies arrived when the print house actually had capacity. That means they were managing two different shipping addresses and timelines, all at once.

Purchase Order #3 had to be sent to the print house with printing specifications that had to sync perfectly with the apparel delivery. Plus, the final shipment required white-label packaging and delivery to the client’s delivery address.

Three vendors. Three timelines. There are about seventeen different ways this could go sideways.

Getting tired of playing vendor coordination roulette every single day?

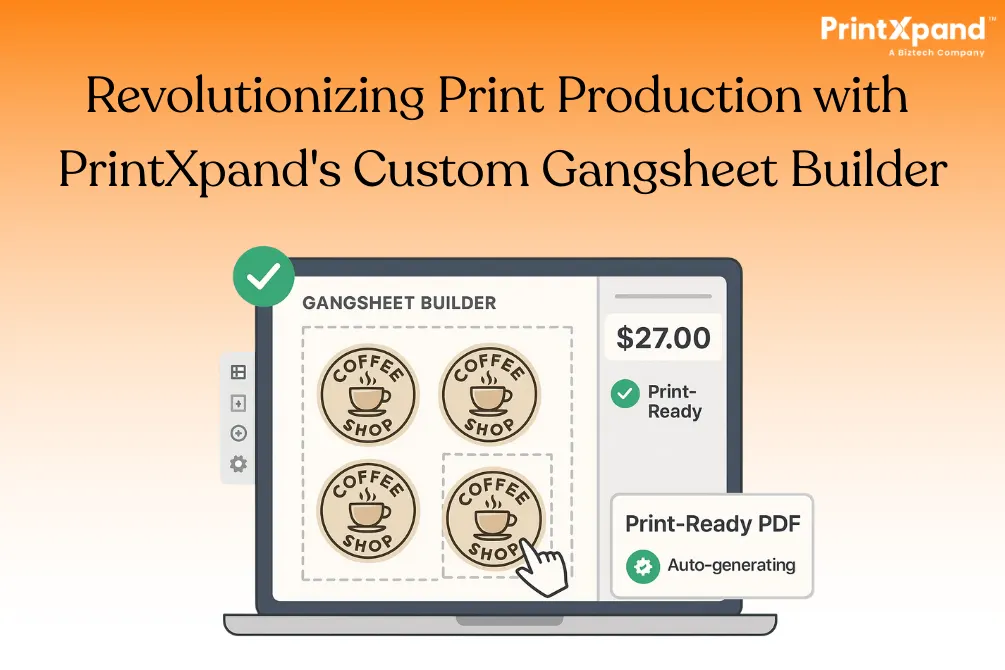

But here’s where it gets really interesting: after client approval, the print order management system automatically generates all three coordinated POs simultaneously. Customer commitment locked through PO #1. Manufacturer fulfillment triggered through PO #2. Print house services initiated through PO #3. Everything is synchronized, tracked, and managed through a single dashboard, rather than three email threads and a prayer.

How the Trade Printer Workflow Works: From Catalogs to Multi-PO Automation

Let’s be honest about something! If you’re still managing wholesale trade printing operations with spreadsheets and email, you’re simply behind the curve, plus you’re playing a completely different game than your successful competitors.

The Catalog Reality Check

Remember those massive binders of product sheets that were outdated before you finished printing them? That’s so 2019. Modern print order management systems integrate directly with manufacturer and print house databases. When pricing changes (and pricing changes constantly these days), your system knows immediately. New products appear automatically. Capability updates happen in real-time.

Results: From Hours to Minutes—and No More Missed Opportunities!

Here are numbers from wholesale trade printers who made the switch—real operations, not hypothetical case studies.

A trade printer in Phoenix was spending 2.5 hours on complex quotes. After implementing proper print order management software, their average quote time dropped to 8 minutes. Their RFQ response rate jumped from 65% to 92% because they could respond the same day instead of saying “by next week.”

Another shop in Seattle was losing approximately $25,000 annually due to pricing calculation errors. After automation, their error rate dropped to essentially zero. Their margins improved 14% in the first year just from accurate pricing.

Curious what these improvements could look like for your operation?